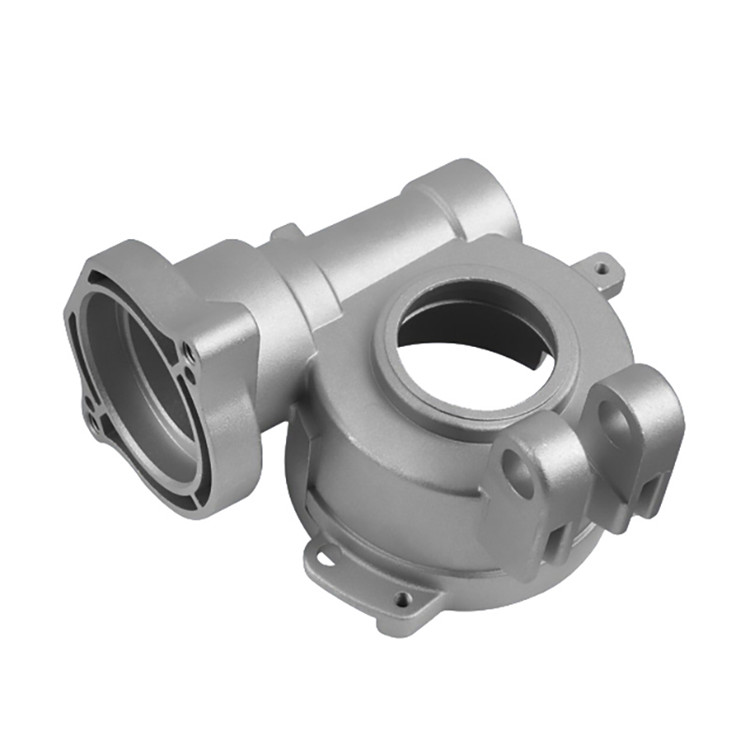

Qaybaha shubka-dhimista ee Zinc Alloy |Xirfadlaha OEM Die Casting

✧ Horudhac Badeeco

Tuubbooyinka dhinta Zinc waxaa loo isticmaalaa in lagu soo saaro qaybo kala duwan iyo qaybo ka mid ah noocyada badan ee codsiyada warshadaha.Sifooyinka farsamaysan ee daawaynta zinc ee ku dhinta heerkulka qolka way ka fiican yihiin kuwa birta cawlan, naxaasta iyo aluminium tuurista ciid, gaar ahaan marka la eego adkaanta iyo xoogga saamaynta.Way ka xoog badan yihiin, ka adag yihiin oo ka cabbir ahaan ka xasilloon yihiin balaastikada la isku duray.Qiimaha la dhimay iyo waxqabadka oo la hagaajiyay ayaa ka dhigaya bedel ku habboon birta, naxaasta, daawaha aluminiumka ama qaybaha balaastikada.

Faa'iidooyinka ku jira shubista alwaaxyada zinc

1. Guryaha wax lagu shubo oo la hagaajiyay - sababtoo ah dheecaankeeda, zinc die castings ayaa laga dhigi karaa mid khafiif ah, kakan oo aad u adag, sidaas awgeedna meesha ka saaraysa baahida habka labaad ee caadiga ah waa in lagu sameeyaa aluminium iyo magnesium alloys.

2. Yaree wakhtiga wareegga - iyadoo ay ugu wacan tahay habka tuurista qolka kulul ee zinc, wax-soo-saarku waa qiyaastii 4 ilaa 5 xabbo daqiiqaddii.Marka la barbardhigo qolka qaboobaha aluminium ee habka shubista dhinta (soo saarista 2 ilaa 3 xaashi daqiiqaddii), waxaa la go'aamin karaa in zinc uu kordhin karo wadarta kaydka sababtoo ah wakhtiga wareegga oo gaaban.

3. Kordhi nolosha caaryada - sababtoo ah heerkulka dhalaalka hooseeya ee zinc, nolosha caaryada qaybaha zinc waxay noqon kartaa 10 jeer ka dheer tii qashinka aluminium aluminium, iyo qiyaastii 5 jeer ka dheer kan caaryada magnesium.

4. Tayada farsamada ee ku habboon - alloy zinc waa ka xoog badan yahay biraha kale ee la midka ah uma baahna farsamaynta labaad.Tayadani waxay badbaadisaa wadarta kharashka qayb kasta.

✧ Sharaxaada Alaabta

| Qalabka caaryada | SKD61, H13 |

| Godka | Keli ama dhowr |

| Caaryada Nolosha Waqtiga | 50k jeer |

| Qalabka Alaabta | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Daaweynta Dusha sare | 1) Polish, daahan budo ah, dahaarka lacquer, e-daahan, ciid qarax, qarax rasaas, anodine 2) Dahaarka Polish + dahaarka Zinc/Dabaynta chrome/Parl Plating chrome Plating/Nikel Plating/Copper Plating |

| Cabbirka | 1) Marka loo eego sawirada macaamiisha 2) Marka loo eego saamiga macaamiisha |

| Qaabka Sawirka | tallaabo, dwg, igs, pdf |

| Shahaadooyinka | ISO 9001:2015 & IATF 16949 |

| Muddada Lacag-bixinta | T/T, L/C, Hubinta Ganacsiga |